Overview

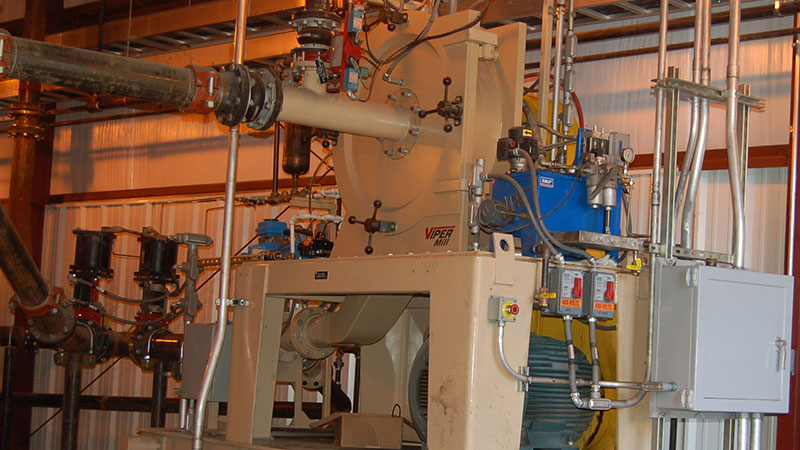

UCC’s industry-leading sorbent particle size reduction technology, VIPER Mill, promotes efficient DSI system operation. Its consistent and reliable performance allows easier performance predictability and consistent operation, while significantly reducing sorbent consumption.

Specifications

Model 150VR

• Sorbent Throughput: 2 – 7 ton/hr

• Line Size: 6” and 8”

• Airflow: 1200 – 2400 SCFM

• Available Motors: 100HP, 125HP, and 150HP

• Power: 3 Phase/60HZ/460 VAC

Model 100VR

• Sorbent Throughput: 0.5 – 2 ton/hr

• Line Size: 3” and 4”

• Airflow: 300 – 600 SCFM

• Available Motors: 100HP and 75kW

• Power: 3 Phase/60HZ/460 VAC

How can we help?

Our team of experts are happy to help answer any questions you have about UCC’s air solutions.